Ever since the discovery and implications of oil and fossil fuels, the world has been powered by non – renewable resources. Now as oil prices increase, oil reserves are being depleted, and with CO2 emissions creating climate change, the world scrambles to find safe, sustainable, clean energy for the future. A popular approach to solve this issue is with the development of biofuels (fuels created directly from living matter) like biodiesels. Although biofuels are already being produced from corn, it hinders the production of food by taking high quality soil out of the production of food; however, a new potential alternative has been found. New research has shown that algae produces the components that create biodiesel, a biofuel used as a substitute. This article is on the experiments, results, and implications of algae as a possible, renewable, biofuel energy source.

The materials used in this experiment consisted of using five different breeds of algae, five different organic carbon sources, and four different growing mediums to see which produced the highest lipid (fatty acids that cannot be dissolved by water like natural oils and waxes) productivity, microalgae growth, and lipid accumulation.

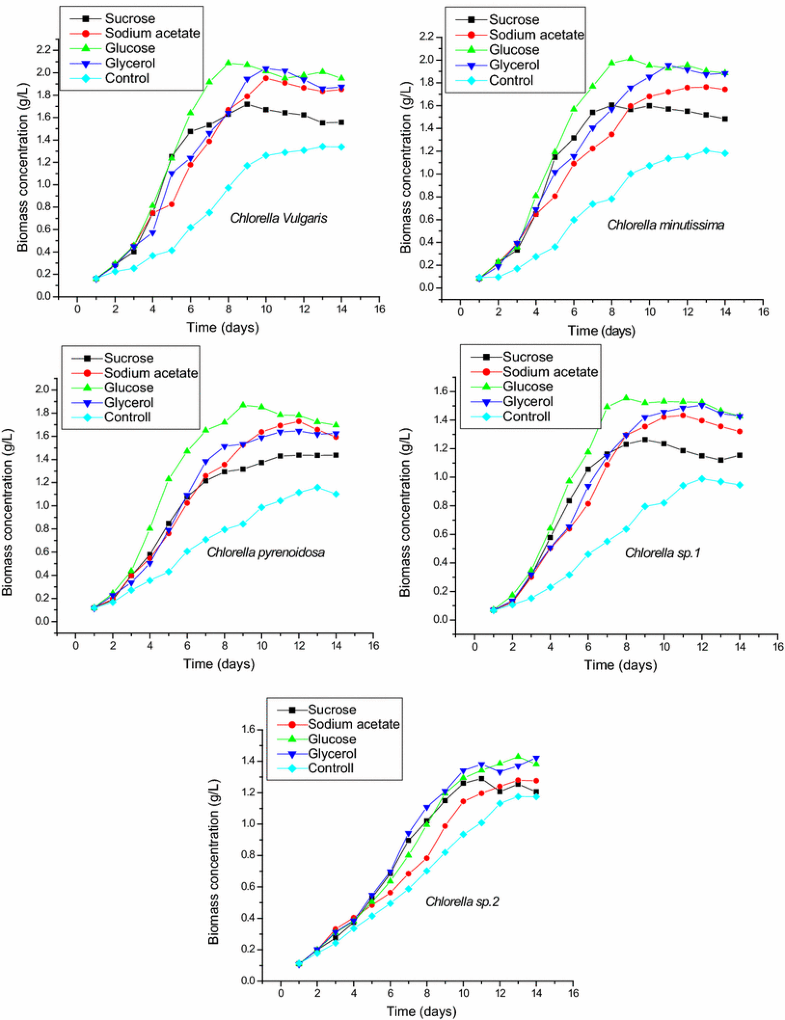

The team of researchers placed a different breed of algae into a different growing medium along with a different carbon source and recorded the data of the yield of lipid productivity; once the most effective medium was discovered, they used that medium and used the varying carbon sources to measure which had the highest growth and lipid accumulation. They also tested to see the effectiveness of the biodiesel produced to see how it would work in the real world by seeing if it would meet the standards that normal fossil fuel diesel is required to meet.

The results of the experiment showed that all breeds of algae studied showed great potential in the same growing medium, BG-11, and the same carbon source, glycerol (fermented glucose). Although all the breeds showed high potential, Chlorella vulgaris showed the highest potential of them all; the lipid yield was 490.74 ± 12.30 mg/L. The second highest was Chlorella minutissima, with only 369.13 mg/L as the maximum yield. Chlorella vulgaris also had the highest lipid productivity compared to the other algae. This is a very promising result because a high fatty acid composition of algae is extremely influential to achieving the required fuel properties. This could mean that Chlorella vulgaris could be an excellent substitute to traditional fossil fuels.

Although it shows high potential, biodiesel made from algae is not ready for large-scale production. To run, biodiesel requires a certain percentage of polyunsaturated fatty acids (similar oils and fats that are found in corn and soybean oil) and Chlorella vulgaris meet the requirements in room temperature, but it was unable to operate in low temperatures. Diesel fuel must be able to crank the engine at a CP range (temperature in which diesel fuel crystallizes) of -3 to 12 Celsius and a PP range (temperature in which the fuel can be poured) of -15 to 20 Celsius; Chlorella vulgaris was only able to have a CP range of 6.43 to 14.86 Celsius and PP range of 0.16 to 9.32 Celsius.

This experiment showed that algae is a very promising alternative to growing corn for biofuel, and when grown in the right medium and with the right carbon source, can be a clean alternative to fossil fuels. The highest lipid yielding algae is also very easy to propagate and it reaches the maximum yield with a little wait time; it also saves much farmland from biofuel production. Although the capabilities seem limitless, further research must be done. The CP and PP ranges of algae biodiesel must be the same as current diesel. Once these ranges are met and algae biodiesel can be produced large – scale, it may end the world’s dependence on fossil fuels forever. This research was conducted by a team lead by Amit Kumar Sharma at University of Petroleum and Energy Studies.

Graphs of the Biomass Growth of the Strains of Algae